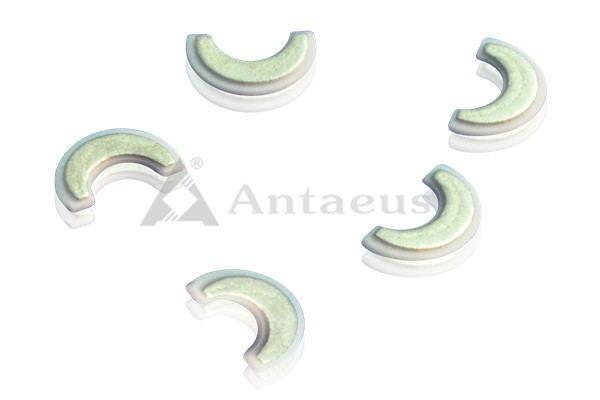

Electrical Component Metallized Alumina Ceramic / Metallization

Ceramic Insulators

1. Description:

The metallization of alumina ceramics (92 pct purity) was performed

by the molybdenum-manganese (Mo−Mn) process in moist hydrogen and nitrogen atmosphere in the

temperature range of 1250 °C to 1400 °C for 10 minutes with a dew

point of 20 °C . The metallized alumina ceramics were characterized

by X-ray diffraction (XRD), scanning electron microscopy (SEM),

energy dispersive X-ray analysis (EDX), evaluation of metallic

coating adhesion by scratch test, and nanohardness measurement. XRD

identified the phase composition of the metallized layer surface.

The surface and cross-section microstructures of the metallized

alumina ceramic specimens were observed by SEM. An EDX analysis

across the metallized alumina specimens determined the elemental

compositions at the selective regions. The scratch test results

showed that the adhesion of the metallized layer on alumina

ceramics enhanced with the increase in metallization temperature.

Nanohardness measurements along the cross-sectional region of the

metallized alumina ceramics exhibited the gradual change in the

nanohardness values from the alumina substrate to the metallizing

layer. Furthermore, it was observed that the nanohardness of

interfacial and metallizing regions was enhanced slightly with

increasing processing temperature.

2. Feature Advantages:

1) High elasticity modulus

2) High compressive strength.

3) Anti corrosion

4) Abrasion resistance

5) Impact resistance

6) High precision

7) High stability

8) Good advanced ceramic materials

9) High welding sealing performance

10) High hardness and high density

11) Low thermal conductivity

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

16) High temperature resistance

17) A variety of specifications is available

18) Satisfy various technical requests

19) Lower medium spoilage

20) Stiffness texture

3. Material Features / Properties:

| Composite | (wt %) | 99% | 99.5% | 99.8% |

| Color | | White or Ivory | White or Ivory | White or Ivory |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics |

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | | Pass | - |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | | Pass | Pass | Pass | - | - | - |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | | ≤8 | - |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | | - | 4 |

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ |

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - |

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - |

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding

--- Printing --- Nickel Plating --- Assembing --- Brazing ---

Inspecting --- Packing

6. Production Facilities: Prilling Tower , Forming Machine , High

Temperature Sintering Kiln

7. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer ,

Granulometer , Helium Mass Spectrometer Leak Detector , Universal

Pull Force Meter

8. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ;

Good Service

9. Shipping and Package:

Notes:Above information only for reference and please contact with

us for more details freely when you have any inquiry!