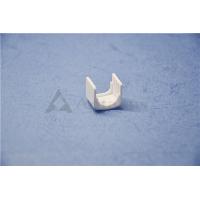

HVDC Relay Machining Alumina Ceramic 95% Alumina Based Ceramics

1. Description:

Different types of electric batteries have different travel range

and efficiency. The lead-acid battery is most available and

inexpensive and is capable of up to 130 km per charge. Following

this, nickel-based batteries have higher specific energy than

lead-acid and can have more than 200 km of range. Finding the

economic balance of range, performance, battery capacity, and

weight pose challenges to any electric vehicle manufacturer.

2. Feature Advantages:

1) High elasticity modulus

2) High compressive strength.

3) Anti corrosion

4) Abrasion resistance

5) Impact resistance

6) High precision

7) High stability

8) Good advanced ceramic materials

9) High welding sealing performance

10) High hardness and high density

11) Low thermal conductivity

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

16) High temperature resistance

17) A variety of specifications is available

18) Satisfy various technical requests

19) Lower medium spoilage

20) Stiffness texture

21) Widely apply for automotive ceramic sensor , ceramic heater

,electric heating

3. Material Features / Properties:

| Composite | (wt %) | 99% | 99.5% | 99.8% |

| Color | | White or Ivory | White or Ivory | White or Ivory |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics |

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | | Pass | - |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | | Pass | Pass | Pass | - | - | - |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | | ≤8 | - |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | | - | 4 |

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ |

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - |

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - |

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding

--- Inspecting --- Packing

6. Application Fields:

New energy vehicles, charging piles, solar power generation, energy

storage and power storage system, electric vehicle power system and

so on.

7. Production Facilities: Prilling Tower , Forming Machine , High

Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer ,

Granulometer , Helium Mass Spectrometer Leak Detector , Universal

Pull Force Meter

9. Order Flow Steps as belows: Inquiry ---Quotation --- Place an

order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ;

Good Service

11. Shipping and Package:

12. Our aimed market:

Loudi Antaeus Electronic Ceramic Co.,Ltd is one of the leading and advanced ceramic material companies in

China, integrating the design, manufacture and marketing of

electronic ceramics and assemblies. Brand name "Antaeus" is formed

almost 20 years. We specialize in Alumina ceramics, Zirconia

ceramic products. We have developed advanced skills and

technologies. Our products are widely used in for new energy

vehicles,electricity, information, power, automobile and other

fields.

Industrial Ceramics: alumina oxide ceramics, zirconia

ceramics,silicone carbide ceramics, silicon oxide ceramics, special

ceramics, high-frequency ceramics, refractory ceramics, electronic

ceramics, textile ceramics, high purity alumina crucible,

electrical ceramics, etc.

Antaeus strictly complies with ISO9001 quality management system.

Our products are widely used in new energy vehicles power,

aerospace, mining machinery, lift, power, paper making, laboratory,

nonferrous metal processing, electronics processing, textile

machinery and other industries.Our customer base, which includes

many Fortune 500 companies.

Application:

These Advanced technical ceramic components find application in a

number of industries, some of them being sealing technology, pumps,

wire-drawing, battery/ cell manufacturing, sand-blasting, chemical,

electronics, textile, automotive, etc.

Customized are welcome according to your drawings or samples.

FAQs (Frequently Asked Questions)

Q1. Are you a factory or trading company?

A: We are a manufacturer of over 19 years of experience. Welcome to

visit our factory.Factory address is Loudi Economy and

Technological Development Zone,Hunan,China.

Q2: Do you send a sample to check?

A: Sure, sample in stock is free and freight collect.

Q3: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If

urgent ,Please call us or chat online.

Q4:What is your Capacity?

A:300,000 pcs per day;

Q5: Are the ceramics good quality?

A:We have passed the complete quality-control system

ISO9001,IATF16949, ISO14001 and IRIS certification. We have more

than 200 advanced testing equipment and instruments,All the Alumina

ceramics are 100% fully inspected,including IQC, IPQC, FQC, and OQC

process.

Q6:What is the Lead time?

A: About 15-35 days,according to the quantities required;

Q7: Is it available to provide customized products?

A:We can do OEM and ODM.

Notes:please feel free to contact us for more details when you have any inquiry!

Loudi Antaeus Electronic Ceramic Co.,Ltd

Factory address:Loudi Economy and Technological Development

Zone,Hunan,China.

Contact person:Alice Deng

Tel:+8615073852630 (wechat)

Mail: alice@andidz.com

Skype: alicedeng0629