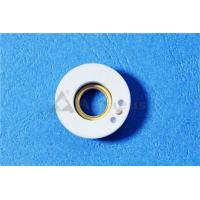

Alumina Advanced Technical Ceramics / Metallized Ceramic Parts

1. Description:

Co-fired ceramic packages are fabricated through four distinct

processing stages that include material preparation, green

processing, sintering, and post-fire processing. Material

preparation consists of milling raw materials into a dielectric

"green tape" as well as conductive inks. Green processing consists

of punching cavities, via punch, via fill, screen printing and

lamination. Once the green process is complete, the ceramic/metal

composite is "co-fired" in a carefully controlled atmosphere. Post

fire processing consists of additional printing, sawing, machining

and brazing. Almost all packages are plated with Ni and Au for

solder and wirebond applications. AdTech Ceramics offers both

electroless and electrolytic plating options, as well as a variety

of thin filmed variations.

Feature Advantages:

1) High hardness and high density

2) Low thermal conductivity

3) Chemical inertness

4) Good wear resistance

5) High Fracture toughness

6) Good insulation performance

7) High temperature resistance

8) A variety of specifications is available

9) Satisfy various technical requests

10) Lower medium spoilage

11) Stiffness texture

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

3. Material Features / Properties:

| Composite | (wt %) | 99% | 99.5% | 99.8% |

| Color | | White or Ivory | White or Ivory | White or Ivory |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics |

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | | Pass | - |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | | Pass | Pass | Pass | - | - | - |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | | ≤8 | - |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | | - | 4 |

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ |

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - |

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - |

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding

--- Printing --- Nickel Plating --- Assembing --- Brazing ---

Inspecting --- Packing

6. Application Fields:

Widely apply for new energy vehicles, charging piles, solar power

generation, energy storage and power storage system, electric

vehicle power system and so on.

7. Production Facilities: Prilling Tower , Forming Machine , High

Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer ,

Granulometer , Helium Mass Spectrometer Leak Detector , Universal

Pull Force Meter

9.Order Flow Steps as belows: Inquiry ---Quotation --- Place an

order --- Production --- Delivery

10. Our advantages: Quality Assurance ; Price Competitive ; Factory Supply Directly ;

Good Service

11.Shipping and Package:

12. Our aimed market :

Notes:Above information only for reference and please contact with

us for more details freely when you have any inquiry!